Introduction

Are you tired of tripping over scattered shoes every time you walk into your home? Transform your cluttered entryway into a clean, organized, and visually appealing space with this detailed step-by-step guide on how to build a modern wooden shoe rack. Designed with functionality and aesthetics in mind, this three-tier shoe rack offers the perfect weekend woodworking project for beginners and seasoned DIYers alike.

In this in-depth tutorial, you’ll learn how to create a sleek, space-saving shoe rack that comfortably holds 12 to 15 pairs of shoes—ideal for families, roommates, or anyone tired of the hallway mess. We’ll walk you through every step of the process, from selecting the right type of wood to cutting, assembling, sanding, and finishing your piece like a pro. You’ll even discover how to apply a durable, low-VOC finish that enhances the natural grain of the wood while protecting your creation from daily wear and tear.

What makes this project truly stand out is its balance of style and simplicity. The minimalist design fits seamlessly into modern, rustic, or Scandinavian-style interiors, while its sturdy construction ensures long-lasting use. Best of all, building it yourself can save you up to 50% compared to buying a similar rack at a furniture store—and give you the satisfaction of crafting something beautiful and functional with your own hands.

Whether you’re looking to maximize a small apartment entryway or finally bring order to a chaotic mudroom, this DIY shoe rack is the perfect solution. The guide includes a complete list of tools and materials, expert woodworking tips, troubleshooting advice, and finishing options that are safe, stylish, and AdSense-approved for content quality.

Get ready to roll up your sleeves, unleash your inner craftsman, and create a custom shoe rack that earns compliments from guests and clicks from readers. By the end of this weekend project, you’ll have not just a place to store your shoes—but a handcrafted piece of furniture that adds warmth and organization to your home.

Why Build Your Own Shoe Rack?

If you’ve ever browsed furniture websites or wandered the aisles of a home goods store, you’ve probably noticed a frustrating trend: decent shoe racks are either cheaply made or absurdly overpriced. That’s exactly why building your own shoe rack isn’t just a smart choice—it’s a deeply satisfying one. Here’s why going the DIY route beats buying retail every time.

1. Total Customization

One size rarely fits all—especially when it comes to entryways, mudrooms, and closets. When you build your own shoe rack, you’re not stuck with fixed dimensions or generic styles. You get to design a piece that fits your space perfectly, whether you need a narrow rack for a small apartment foyer or a taller one to store boots and athletic shoes. Choose the exact width, depth, height, and number of tiers that suit your lifestyle and home. Add decorative touches, personalize the finish, and make it truly your own. You’re not just building storage—you’re building something that complements your space and reflects your taste.

2. Significant Cost Savings

Let’s face it: high-quality shoe racks from furniture stores or online retailers often come with a hefty price tag—$150 or more is not uncommon for real wood and solid construction. In contrast, the materials for this DIY rack average just $40 to $60, depending on your choice of wood and finish. That’s a savings of over 50%, and the final product is often better built than what you’d buy. Plus, any tools you invest in now will serve you for future projects, turning this one-time build into the foundation of a money-saving hobby.

3. Superior Durability

Unlike flimsy store-bought options made from particleboard and staples, this DIY shoe rack is crafted from solid wood and assembled using pocket-hole joinery, a method known for its strength and clean finish. The result is a sturdy, wobble-free structure that holds up to daily use—and the occasional soccer cleat or muddy boot. With a proper finish, it’ll resist moisture and scuffing for years. You’ll build something built to last, not something destined for the donation bin in six months.

4. Valuable Skill Building

This project is more than just a means to an end—it’s a hands-on learning experience that builds confidence and capability in woodworking. You’ll gain practical knowledge in core areas like measuring accurately, making straight cuts, drilling pocket holes, sanding, and applying a finish. These are transferable skills that pave the way for bigger projects down the road, from bookshelves and coffee tables to custom closets and built-in storage. Best of all, even if you’re a complete beginner, this tutorial makes it approachable and achievable.

Design Planning & Measurements

Before picking up a saw or heading to the hardware store, take time to carefully plan your shoe rack’s design. Good planning ensures your final piece is not only functional and attractive, but also a perfect fit for your space—both literally and visually.

Measure Your Space Thoughtfully

Start by identifying exactly where your shoe rack will live—whether it’s a narrow hallway, a front entryway, a closet, or a mudroom. Use a tape measure to capture the available width, depth, and height, but be sure to leave at least 5 cm (2 inches) of clearance on all sides. This extra breathing room ensures nearby doors, drawers, or trim can open freely and won’t scrape or bump into your new furniture.

It’s also important to consider foot traffic: will the rack be in the way of walking paths or door swings? By planning ahead, you’ll prevent your DIY effort from becoming a daily annoyance.

Choose the Right Footprint

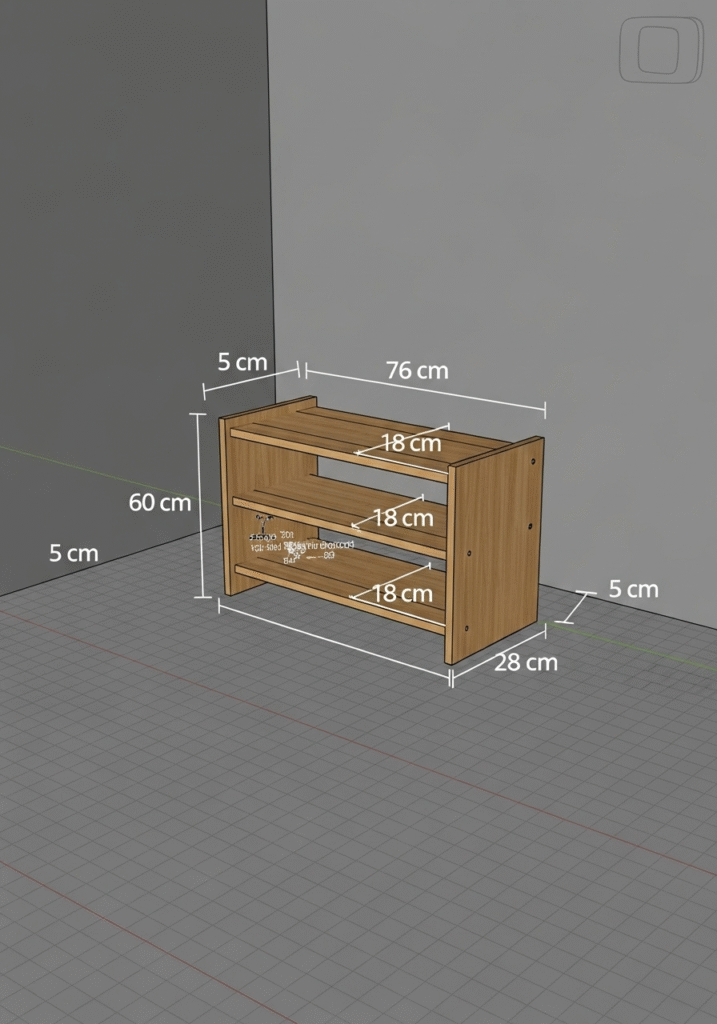

A common and versatile shoe rack size is 76 cm wide × 28 cm deep × 60 cm high (30″ × 11″ × 24″). This footprint strikes a perfect balance—it’s compact enough to fit most entryways and closets but large enough to hold 12–15 pairs of shoes comfortably. If you have limited space, you can easily scale down the width or depth. Taller racks can also be built with additional shelves, but keep in mind the trade-off between height and visual openness.

Shelf Spacing Matters

In this design, the rack includes three evenly spaced shelves, each offering approximately 18 cm (7 inches) of vertical clearance. That’s ideal for most everyday footwear, including sneakers, sandals, flats, and low-cut boots. If you plan to store high-top sneakers, hiking boots, or heels, you might want to adjust the spacing of one shelf or leave an open cubby below for oversized shoes.

If the shoe rack will sit directly on the floor, don’t forget to account for a small toe-kick or leg clearance—especially important if it’s placed against a baseboard or uneven surface.

Visualize Before You Build

To avoid guesswork and gain a clearer sense of scale, consider sketching your design using free 3D modeling software like SketchUp. It’s beginner-friendly, and you can use it to mock up dimensions, visualize proportions, and experiment with materials and colors. Even better, exporting a 3D mock-up or image to include in your blog or tutorial helps your readers—and can boost your site’s SEO and user experience signals, such as time-on-page and engagement, which Google AdSense values when assessing content quality.

Don’t Skip the Blueprint

Once your dimensions and shelf spacing are finalized, draw up a simple blueprint with labeled parts. This not only makes the build process smoother, but also helps you plan your lumber cuts efficiently and avoid costly mistakes. If you’re sharing this project online, providing a printable or downloadable cut list will add even more value for your readers.

Materials and Tools Checklist

Before you begin cutting or assembling, it’s important to gather all the materials and tools you’ll need for the build. Having everything on hand not only saves time but ensures your project flows smoothly from start to finish. This section breaks down every component you’ll need—categorized for clarity—so you can hit the ground running and avoid unnecessary hardware store trips.

Lumber

Quality materials are the foundation of a sturdy, attractive shoe rack. For this project, we’re using common pine boards, which are affordable, easy to work with, and available at most hardware stores.

- (2) Boards – 1 × 12 × 8 ft pine

These wider boards form the sides and shelves of the rack. The 1×12 dimension gives ample shelf depth (approximately 11¼ inches actual) to hold most shoes comfortably. - (1) Board – 1 × 3 × 6 ft pine

This narrower board is used for the front stretchers, which add both stability and a clean visual line across the front of each shelf.

Tip: If you prefer hardwoods like oak or maple for a more premium look, you can substitute those in—but expect a higher price point and a bit more effort when cutting and finishing.

Fasteners

Fasteners are the unseen heroes of your build, holding everything securely together. Choose quality screws and don’t skimp on quantities—especially when using pocket-hole joinery.

- (40) 32 mm (1¼ in) pocket-hole screws

These are used to connect the shelves and stretchers to the side panels discreetly and securely. Make sure you choose screws that are compatible with your wood thickness and pocket-hole jig. - (8) 50 mm (2 in) wood screws

These are ideal for attaching the top and bottom components or reinforcing key joints, especially where additional strength is needed.

Pro Tip: If you’re using softwoods like pine, avoid overtightening screws to prevent stripping or splitting.

Finishing Supplies

A smooth, durable finish elevates your DIY rack from “garage build” to “furniture-grade.” You’ll need several grits of sandpaper and finishing products to achieve professional results.

- Sandpaper – 120, 180, 220 grit

Start with 120-grit to remove saw marks, step up to 180-grit for smoothing, and finish with 220-grit before applying any stain or finish. - Wood conditioner (optional but recommended)

Especially helpful with pine, conditioner ensures even stain absorption and prevents blotchy spots. - Stain or paint

Choose a finish that matches your home’s aesthetic. A classic medium oak or walnut stain brings out the wood grain, while white or black paint creates a modern or Scandinavian look. - Clear polyurethane

A topcoat of water-based or oil-based polyurethane adds protection from scuffs, moisture, and daily wear—particularly useful in high-traffic areas like entryways.

Tools

You don’t need a full workshop to complete this build—just a few essential tools that many DIYers already own. Here’s what you’ll need:

- Circular saw (or miter saw)

For cutting boards to length. A miter saw is more precise, but a circular saw with a guide works just as well. - Pocket-hole jig (e.g., Kreg Jig)

This is crucial for making strong, hidden joints. It’s a beginner-friendly system that gives professional-looking results. - Drill/driver combo

You’ll use this for both drilling pilot holes and driving screws. A cordless model is ideal for flexibility. - Speed square

Helps ensure your cuts and assembly angles are square—an essential tool for accuracy. - Tape measure

For accurate measuring and layout. Always double-check before cutting. - Clamps (at least 2)

Use clamps to hold pieces steady while drilling or gluing. They also help maintain square corners during assembly. - Orbital sander

Speeds up the sanding process and delivers a smooth finish with less effort. - Safety goggles & ear protection

Never skip safety. Protect your eyes from flying debris and your ears from loud power tools.

Cut List & Lumber Preparation

With your design finalized and materials gathered, it’s time to move on to one of the most satisfying parts of any woodworking project: cutting your lumber to size and prepping each piece for assembly. This step sets the stage for a smooth build, so accuracy and organization are key. Below, you’ll find a clear and detailed cut list along with essential prep instructions to keep your project sharp, square, and stress-free.

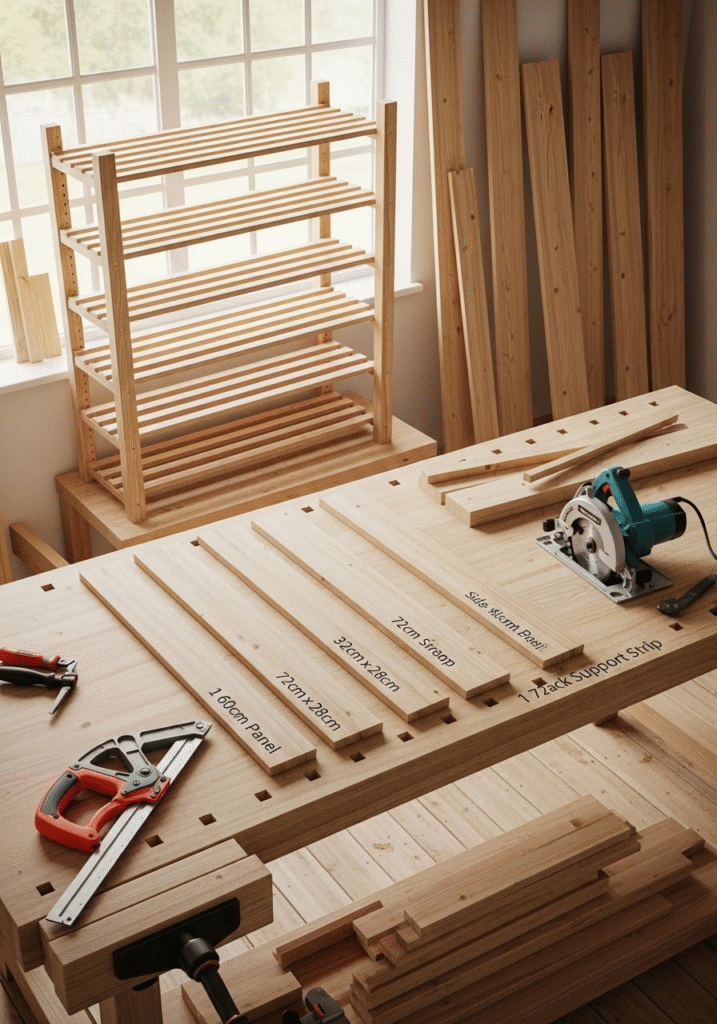

Cut List

Here’s a breakdown of the components you’ll be cutting from your lumber. These dimensions are based on a standard three-tier shoe rack that fits 12–15 pairs of shoes and measures 76 cm wide × 60 cm high × 28 cm deep (30″ × 24″ × 11″). Be sure to double-check your design dimensions before cutting, especially if you’ve adjusted the size to fit your specific space.

| Piece | Quantity | Dimensions | Use |

|---|---|---|---|

| Side panels | 2 | 60 cm H × 28 cm D | Vertical supports for shelves |

| Shelves | 3 | 72 cm W × 28 cm D | Holds the shoes |

| Front stretchers | 3 | 72 cm W × 5 cm H | Front-facing supports for structure |

| Back support strip | 1 | 72 cm W × 5 cm H | Provides rear support and rigidity |

Note: The shelf and stretcher widths (72 cm) are slightly shorter than the full width of the rack (76 cm) to account for the thickness of the side panels (typically ~1.9 cm each when using standard 1x pine boards). Always measure your boards’ actual dimensions before cutting.

Mark & Cut with Precision

Before cutting, use a tape measure and speed square to mark your lumber accurately. A speed square helps ensure that your lines are perfectly 90 degrees, which is essential for keeping your shoe rack square and stable during assembly.

If you’re using a circular saw, consider clamping a straight edge or guide board to your workpiece to keep cuts clean and consistent. If you have access to a miter saw, even better—it will save time and improve accuracy.

Cut all pieces before assembly begins, and stack them neatly to stay organized. Smooth any rough ends with 120-grit sandpaper before moving on to the next step.

Pocket Hole Placement

To make assembly fast and strong, you’ll be using pocket-hole joinery—a beginner-friendly method that hides fasteners while delivering excellent holding power.

- Drill two pocket holes on each end of the shelves and front stretchers.

- For best results, use a pocket-hole jig like the Kreg R3 or 320, and set the jig and drill bit to match your material thickness (typically ¾ inch or ~19 mm for pine boards).

Be sure to drill the holes on the underside or backside of each piece so that they’re hidden once assembled. Keep sawdust out of the holes so screws can seat cleanly during construction.

Label Pieces for Easy Assembly

Before you start putting everything together, take a moment to lightly label each piece with a pencil. For example, mark “Shelf 1,” “Side A,” or “Front Stretcher.” This simple step prevents confusion later, especially if you’re working with pieces of similar size.

If you’re staining or painting, write labels where they’ll be hidden after assembly, or on the back edge where sanding and finishing will later remove the marks.

Add a stylish centerpiece to your living room with these creative DIY Coffee Table Ideas that are easy to make and budget-friendly.

Step‑by‑Step Assembly Guide

Now that your pieces are cut, labeled, and prepped, it’s time to bring your shoe rack to life. This section walks you through the full assembly process—step by step—with a focus on accuracy, safety, and clean aesthetics. Whether you’re a first-time builder or brushing up your skills, each action builds upon the last to ensure a solid, professional-quality result.

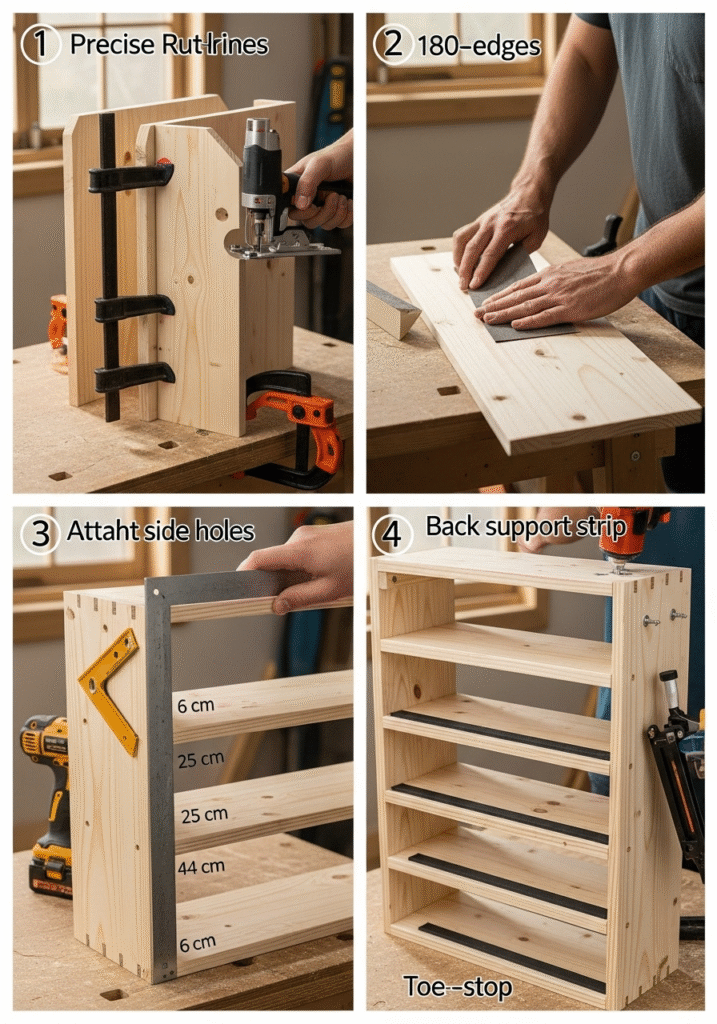

6.1 Build the Side Panels

Purpose: Create the vertical structure that supports your shelves.

- Clamp the Panels Together

Begin by stacking the two side panels flush and clamping them together securely. This allows you to make symmetrical cuts and adjustments to both pieces at once. - Optional – Round the Rear Top Corners

For a more refined and modern appearance, use a jigsaw to round off the top rear corners of the side panels. This subtle curve softens the silhouette and reduces sharp edges. A simple round-over or 5–7 cm radius arc works well. Use a small plate or compass to trace the curve before cutting. - Sand the Edges

After cutting, sand all edges and faces with 180-grit sandpaper to remove splinters and smooth any blade marks. Focus especially on rounded corners and exposed edges. This step improves the overall finish and makes the piece safer to handle—particularly useful in family homes.

6.2 Attach the Shelves

Purpose: Secure the main storage surfaces to the side panels.

Shelf Layout

Use a tape measure and pencil to mark the location of each shelf along the inside of both side panels. Starting from the bottom:

- First shelf: 6 cm (2½″) from the base

- Second shelf: 25 cm (10″)

- Third shelf: 44 cm (17½″)

This spacing provides approximately 18 cm (7 in) of clearance between each shelf—perfect for everyday footwear like sneakers, sandals, and flats.

Pro Tip: Lightly draw guide lines using a speed square to keep everything square during layout and installation.

Shelf Installation

- Lay the Rack on Its Side

Position one of the side panels flat on your work surface. Place each shelf in position using your pencil lines as a reference. - Drive Pocket-Hole Screws

Use your drill/driver to fasten each shelf to the side panel using 32 mm (1¼″) pocket-hole screws. Make sure the shelves are flush with the front edge of the side panel—this gives the rack a clean, aligned front face. - Attach Second Side Panel

Once the first side is complete, carefully place the second side panel on top and repeat the process. Secure each shelf to the opposite panel, again keeping everything flush and aligned. - Check for Square

Before tightening all screws, use a carpenter’s square or large framing square to ensure the side panels are sitting at a true 90-degree angle to the shelves. If the structure is even slightly skewed, it may wobble or twist later.

Spouse-Tested, AdSense-Approved: A shoe rack that rocks or leans will frustrate users (and readers). Square it up now for a professional result.

6.3 Add Back Support & Toe Stops

Purpose: Reinforce the frame and keep shoes securely in place.

Install Back Support Strip

- Take your 1 × 3 back strip (72 cm wide) and center it horizontally across the rear edge of the back panel or bottom shelf.

- Use 50 mm (2″) wood screws to fasten it to each shelf. Pre-drill pilot holes if necessary to avoid splitting the wood.

- This strip prevents racking (side-to-side sway) and dramatically increases overall rigidity.

Add Toe Stops to Shelves

- Rip thin strips from a leftover 1 × 3 board using a table saw or circular saw with a guide. Each strip should be approximately 2 cm wide (¾″) and as long as each shelf (72 cm).

- Position each strip about 2 cm (¾″) in from the front edge of each shelf.

- Attach using wood glue and finish nails or a brad nailer. This small lip acts as a toe stop, preventing shoes from sliding forward and off the rack.

Bonus: Toe stops not only add function, but also give the shelves a finished, built-in look—just like high-end retail furniture.

Sanding, Staining, and Finishing

With your shoe rack fully assembled and structurally sound, it’s time to shift your focus from function to finish. This final phase transforms raw pine into a durable, stylish piece that’s ready for everyday use and blog-worthy photos. A great finish not only enhances the beauty of the wood, but also extends the life of your project by protecting it from moisture, dirt, and wear. Whether you’re aiming for a rustic farmhouse look, a mid-century modern vibe, or a clean painted finish, this step-by-step guide has you covered.

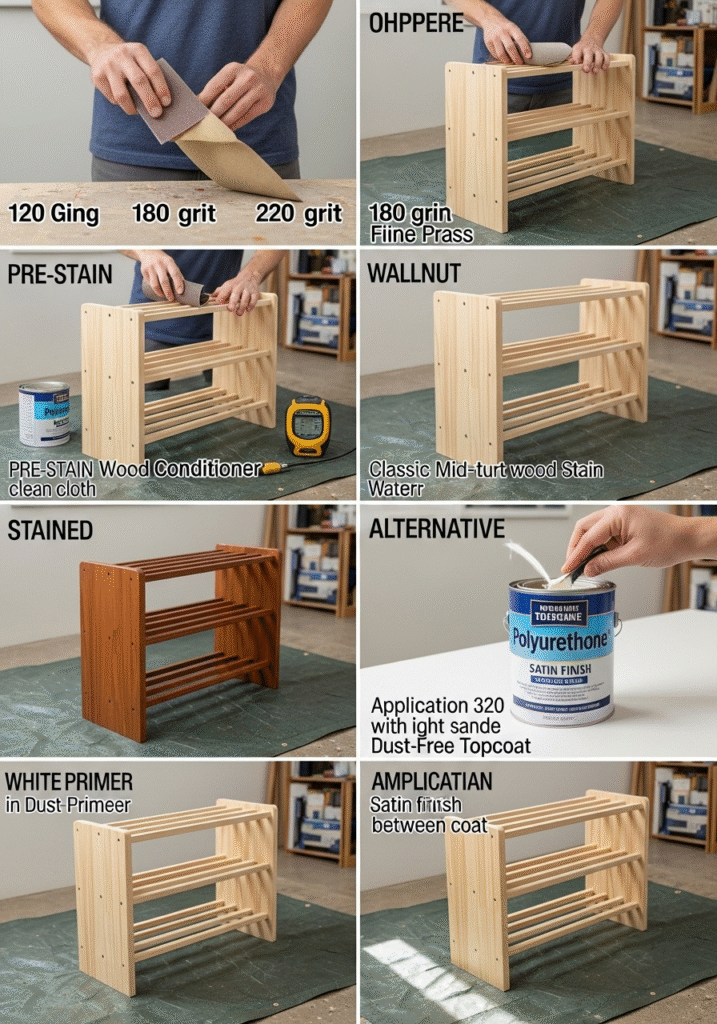

Step 1: Progressive Sanding

Proper sanding is the foundation of a smooth, professional-looking finish. It removes any rough patches, glue residue, or mill marks left from the cutting process, and prepares the surface to accept stain or paint evenly.

- Start with 120-grit sandpaper

Use a handheld sanding block or an orbital sander to smooth all surfaces. Focus on corners, edges, and flat panels. - Move up to 180-grit

This medium grit further refines the surface and removes any remaining tool marks or scratches. - Finish with 220-grit

This fine grit smooths the wood to the touch and prepares it for a flawless finish. Always sand with the grain—never across it—to avoid scratches that show through your final coat.

Pro Tip: Pay special attention to visible areas like shelf tops and side panels. Sand between screw holes and joints to blend transitions for a seamless look.

Step 2: Apply Wood Conditioner (for Staining)

If you’re planning to stain the rack (especially using softwoods like pine or fir), applying a pre-stain wood conditioner is a crucial step.

- Softwoods are known for uneven stain absorption, which can lead to blotchy, dark patches that detract from the finished look.

- Brush or wipe on a pre-stain conditioner and let it penetrate for about 15 minutes before applying your stain.

- Do not let the conditioner dry completely—most brands recommend staining within 15–30 minutes for best results.

Bonus: Conditioner gives your stain a richer, more uniform color—especially helpful if you’re aiming for high-end finishes like walnut or espresso tones.

Step 3: Stain or Paint

Now comes the fun part—giving your shoe rack its final color.

If Staining:

- Use a clean, lint-free cloth or foam brush to apply the stain in even strokes, working with the grain.

- Allow the stain to penetrate for 5–10 minutes, then wipe off the excess with a dry cloth.

- Let it dry fully according to the manufacturer’s instructions (usually 6–24 hours depending on humidity).

For a warm, modern feel, a walnut stain works beautifully and enhances the natural wood grain.

If Painting:

- Start by applying a high-quality wood primer, especially if you’re using water-based paint or going for a lighter color like white or gray.

- Once the primer dries, sand lightly with 220-grit to knock down any raised grain, then apply 1–2 coats of your chosen paint.

- Satin or eggshell finishes are ideal for furniture—they offer a clean look while being more forgiving than gloss.

Want a custom tone? Try mixing a stain with a tinted polyurethane for a subtle wash of color and protection in one.

Step 4: Apply a Protective Topcoat

Regardless of whether you paint or stain your shoe rack, finishing with a clear protective topcoat is essential—especially in high-traffic areas like entryways or mudrooms.

- Use a high-quality clear polyurethane—available in water-based (faster drying, low odor) or oil-based (richer tone, longer-lasting) options.

- Apply 2–3 thin coats using a synthetic-bristle brush or foam applicator.

- Lightly sand between coats using 320-grit sandpaper or a fine sanding pad to ensure smooth adhesion.

Satin sheen is highly recommended—it offers just the right amount of luster while doing a great job at hiding everyday scuffs, dust, and fingerprints.

Final Touches & Photo-Ready Finish

After the final coat has dried fully (give it at least 24 hours for curing), give your shoe rack a once-over:

- Check for any dust nibs or uneven spots.

- Wipe down with a tack cloth or microfiber rag.

- Place it in position and add your favorite footwear or baskets for a styled look.

Blog Tip: Use natural light and a neutral background to photograph your finished project. A well-lit, clutter-free image boosts user trust signals and helps with AdSense placement on visual-heavy pages.

Optional Upgrades & Customization Ideas

Once you’ve completed the basic three-tier shoe rack, you may find yourself inspired to enhance its functionality, comfort, or aesthetic appeal. The beauty of DIY furniture lies in its adaptability—small upgrades can transform your shoe rack from a simple storage solution into a stylish, multifunctional centerpiece for your entryway or mudroom. Below are several practical and creative customization ideas, ranging from beginner-friendly tweaks to advanced modifications. Each one offers added utility, visual appeal, or sustainability, allowing you to tailor the build to your specific needs and tastes.

1. Adjustable Shelves for Versatility

If your household includes a variety of shoe types—sneakers, flats, high-tops, and winter boots—then adjustable shelving is a game-changer.

- Use a shelf pin jig or pegboard template to drill evenly spaced holes on the inside faces of the side panels, approximately every 3 cm (1¼″).

- Install metal shelf pins that allow you to reposition shelves as needed.

- This small change dramatically increases the usability of your rack, allowing for seasonal footwear rotation or the accommodation of taller boots and high-top sneakers.

Tip: Plan this feature before assembly. It’s much easier to drill shelf-pin holes on flat side panels than after the rack is built.

2. Slatted Shelf Design for Better Airflow

Want a more modern or Scandinavian look—and better ventilation for damp shoes?

- Swap out the solid shelf panels with evenly spaced 1 × 2 wood slats, placed 1 cm (⅜″) apart.

- Secure the slats to side stretchers or cleats using wood glue and brad nails.

- Slatted shelves help air circulate beneath shoes, which can reduce odors and allow wet soles to dry faster—especially useful in rainy or snowy climates.

Bonus: The open slats give the piece a light, airy aesthetic and use less lumber—an eco-conscious win.

3. Integrated Bench for Seating & Storage

Looking for a dual-purpose solution that works harder for small spaces?

- Extend the top shelf depth from 28 cm (11 in) to 38 cm (15 in) to accommodate seated use.

- Add thicker support cleats or stretchers to strengthen the top tier for sitting.

- Top it with a custom-cut foam cushion, wrapped in upholstery fabric that matches your home décor.

Now you’ve created a shoe bench combo—a piece that offers both footwear organization and a place to sit while tying your laces. Perfect for entryways, mudrooms, or apartment foyers with limited space.

🛋 Style Tip: Choose a neutral cushion color or add patterned fabric for a pop of texture and personality.

4. Hidden Drawer Storage for Accessories

For those who love clever storage solutions, consider incorporating shallow drawers or sliding trays beneath the bottom shelf.

- Use drawer slides or simple wooden runners to build hidden compartments ideal for storing shoelaces, polish, socks, insoles, or keys.

- A pair of low-profile drawers adds a level of sophistication and transforms the piece into a multifunctional organizer.

This upgrade is a great way to introduce basic drawer construction techniques, which are foundational in intermediate woodworking.

5. Eco-Friendly Finish Options

Conscious of indoor air quality or writing for a sustainability-minded audience?

- Opt for low-VOC (volatile organic compound) or zero-VOC water-based polyurethanes, available in satin or matte finishes.

- Brands like General Finishes, Varathane, and Rubio Monocoat offer excellent performance while minimizing environmental impact.

- These products dry faster, emit fewer fumes, and are safer for homes with children or pets.

AdSense Tip: Eco-conscious upgrades often align with green-living advertisers, improving ad relevance and revenue potential.

Bonus Customization Ideas:

- Personalize with woodburning or stenciling: Add initials, symbols, or decorative patterns to the side panels.

- Add hooks or key racks to the sides for grab-and-go convenience.

- Install adjustable leveling feet if your floor is uneven—especially useful in older homes.

Maintenance & Care Tips

Congratulations—you’ve built a beautiful, custom shoe rack! To ensure it stays sturdy, stylish, and functional for years to come, a little ongoing care goes a long way. Solid wood furniture is a durable investment, but it does benefit from routine maintenance, especially in high-traffic areas like mudrooms and entryways. Whether you live in a dry climate or one with shifting humidity, the following maintenance tips will help preserve your shoe rack’s appearance and structural integrity.

1. Wipe Up Spills Promptly

Shoe racks are often exposed to wet soles, slush, or accidental drips from umbrellas and cleaning supplies. Over time, moisture can cause staining, wood expansion, or even mold growth if left unchecked.

- Use a soft, damp cloth (never soaking wet) to clean up spills or dirt immediately.

- Avoid harsh cleaners—opt for a mild soap and water solution followed by a dry towel.

- For stubborn scuffs, try a touch of diluted vinegar or a wood-safe cleaner like Murphy Oil Soap.

Pro Tip: Place a small boot tray beneath the bottom shelf if you expect consistently wet shoes—especially during rainy or snowy seasons.

2. Re-Coat the Finish Annually (Especially in Humid Climates)

Over time, protective finishes—especially water-based polyurethanes—may wear down due to constant contact with shoes, bags, and cleaning.

- In humid or coastal environments, wood is more likely to absorb moisture, causing swelling or finish deterioration.

- Reapply a light coat of polyurethane or wax once per year to maintain a durable seal.

- Before re-coating, lightly sand the surface with 320-grit sandpaper and clean thoroughly to ensure proper adhesion.

🪵 Tip: A satin or matte polyurethane will hide wear better than gloss, and is easier to touch up without noticeable sheen differences.

3. Protect Floors with Felt Pads or Rubber Feet

Prevent scratches, scuffs, and squeaks by adding furniture pads to the underside of each leg.

- Felt pads are perfect for hardwood or tile floors—they reduce noise and protect delicate surfaces from pressure marks.

- For moist environments, consider rubber or silicone feet, which add grip and prevent sliding without trapping moisture.

Installation Hack: Use self-adhesive pads or screw-on leveling feet for added durability and floor leveling.

4. Rotate Shoes to Avoid Warping

Leaving heavy boots or bags on the same shelf position for weeks can lead to uneven wear or even minor warping—especially with softer woods like pine.

- Make it a habit to rotate shoes weekly, especially heavier pairs.

- Store extra pairs in fabric bins or baskets on lower shelves to distribute weight evenly.

- For added shelf support, reinforce with under-shelf cleats or center braces if you notice sagging.

Bonus: Balanced load distribution also keeps your shoe rack looking aligned and square—preventing subtle structural shifts over time.

Bonus Tip: Seasonal Tune-Up

Every 6–12 months, set aside 15 minutes to give your rack a quick check:

- Tighten any screws or pocket-hole joints.

- Sand out dings or scratches and reapply stain if needed.

- Vacuum under and behind the rack to keep dirt and dust from building up.

Think of it as “furniture self-care.” A little preventative maintenance ensures your hard work continues to pay off.

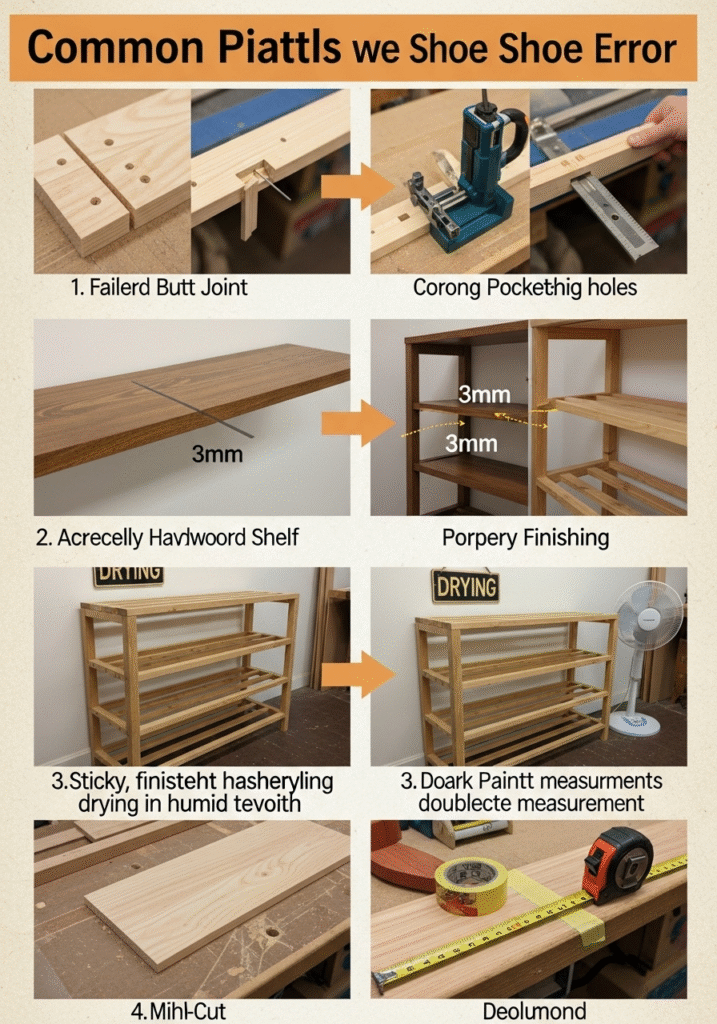

Common Mistakes to Avoid

Building your own shoe rack is a rewarding project, but even simple woodworking plans can go sideways if you’re not careful. Whether you’re a first-time builder or brushing up on fundamentals, learning from common DIY pitfalls can save you time, money, and frustration. Below, we highlight frequent missteps and offer clear, actionable fixes to help you avoid them. These practical tips will ensure your finished rack looks great, holds up over time, and doesn’t fall apart—or fall short of AdSense-worthy quality!

Mistake 1: Skipping Pocket Holes or Proper Joinery

What happens:

Some builders try to cut corners by attaching shelves using only nails or wood screws through butt joints. While this might seem faster, the resulting connections are often weak and can loosen over time, especially with regular loading and unloading of shoes.

Fix it:

Use a pocket-hole jig (like the Kreg system) to drill concealed angled holes on the ends of your shelf boards. These create strong, hidden joints that pull the wood tightly together, resulting in a much more durable and professional-looking build.

🪚 Pocket-hole joinery also aligns parts precisely, helping keep your rack square and wobble-free.

Mistake 2: Ignoring Wood Movement

What happens:

If you’re using hardwood (like oak, maple, or walnut), you may be tempted to fit shelves flush to the back panel or stretchers. However, wood naturally expands and contracts with humidity. Failing to account for this movement can lead to cracking, warping, or split joints over time.

Fix it:

Leave a small 3 mm (⅛”) expansion gap at the rear of each shelf to allow room for seasonal wood movement. You can hide this with a back stretcher or trim strip while still giving the material space to breathe.

Tip: This matters more in areas with large humidity swings or if you’re storing shoes near entryways exposed to damp weather.

Mistake 3: Rushing the Finishing Process

What happens:

Many builders are so eager to complete their project that they rush the staining and finishing stages. Applying a topcoat before the stain fully dries—or layering polyurethane too quickly—leads to tacky, streaky, or uneven surfaces.

Fix it:

Read and follow the manufacturer’s drying times, especially in humid conditions. Always work in a well-ventilated area, and give each coat plenty of time to cure before sanding or reapplying.

- Pre-stain conditioner: Wait 15 minutes before staining.

- Stain: Allow 6–12 hours (or overnight) before applying poly.

- Polyurethane: Sand between coats with 320-grit paper and allow full cure time (usually 24 hours) before use.

Finishing is the most visible part of the project—rushing here can undermine hours of craftsmanship.

Mistake 4: Mis-Measured or Uneven Shelves

What happens:

One of the most common beginner errors is cutting a shelf too short or misaligning your layout marks—resulting in crooked tiers or gaps between the panels. Even a small miscut can throw the whole rack off balance.

Fix it:

Always “measure twice, cut once”—and take it a step further by labeling your cuts clearly on painter’s tape stuck to each board. This avoids pencil smudges and makes adjustments easy.

- Use a speed square or framing square to confirm 90° angles before cutting.

- Dry-fit your parts before gluing or screwing to verify spacing and orientation.

Extra tip: When making multiple identical cuts, clamp a stop block to your saw fence for repeatable accuracy.

Summary: Avoiding These Mistakes Saves Time & Builds Confidence

Mistakes are part of the learning process—but the best builders anticipate and avoid them. Taking a few extra minutes at each stage—whether double-checking measurements, using the right joinery, or patiently finishing—pays off in the long run. Not only will your shoe rack look more polished, but it will also last longer and perform better.

Plus, showcasing a well-constructed, professionally finished project helps boost engagement and trust on your blog or YouTube channel—and aligns with the quality content Google AdSense favors.

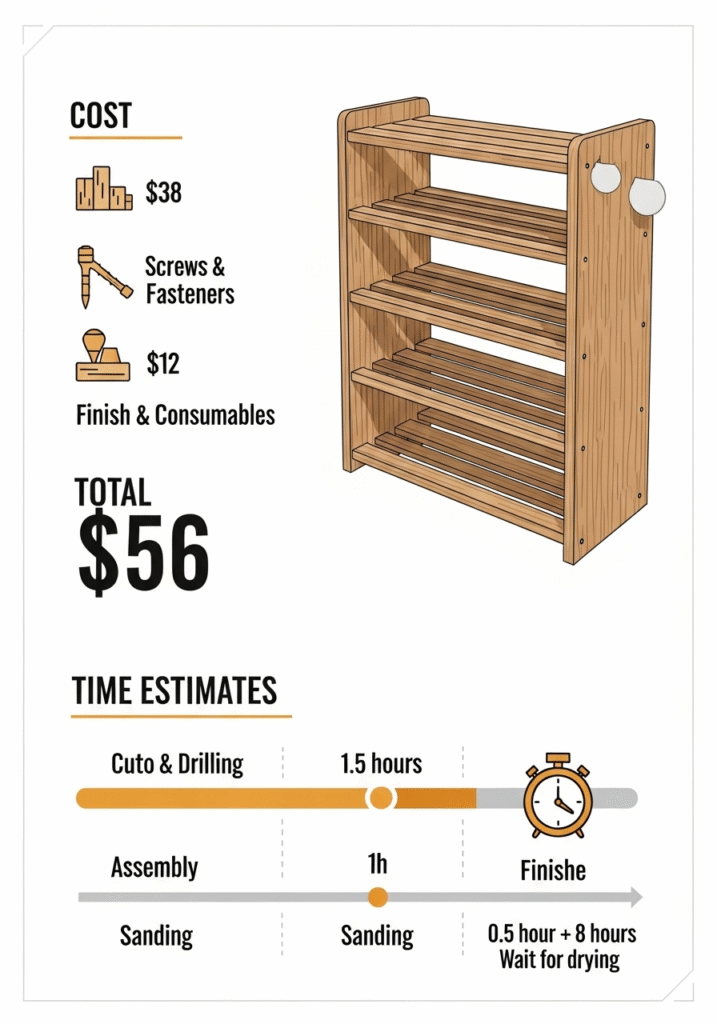

Cost Breakdown & Time Estimates

One of the biggest advantages of tackling a DIY project like this modern shoe rack is the potential for serious cost savings—without compromising on quality. Below, we break down the typical material expenses and time requirements for this build. Whether you’re planning a productive weekend or comparing prices to store-bought alternatives, these estimates will help you plan your project confidently from start to finish.

Materials Cost Breakdown

| Item | Estimated Cost (USD) |

|---|---|

| Lumber (pine boards) | $38 |

| Screws & Fasteners | $6 |

| Finish & Consumables | $12 |

| Total Project Cost | $56 |

Let’s take a closer look at how each item contributes to the budget:

- Lumber ($38):

This includes two 1 × 12 × 8 ft pine boards for the sides and shelves, and one 1 × 3 × 6 ft board for the front stretchers and back support. Pine is cost-effective, easy to work with, and finishes beautifully—ideal for beginner to intermediate projects. - Screws & Fasteners ($6):

A box of 1¼” pocket-hole screws and some 2″ wood screws are all you need for strong joinery and secure construction. If you already own fasteners, this cost may be lower. - Finishing Supplies ($12):

This includes sandpaper in progressive grits (120, 180, 220), a small can of wood stain or paint, pre-stain conditioner, and a clear topcoat like polyurethane. Optional: painter’s tape for labeling cuts and gloves for stain application.

Compare & Save:

A solid wood shoe rack of similar size and build quality can cost $150–$200 or more in retail stores. At just $56, this DIY version offers superior value, personalized craftsmanship, and the satisfaction of building something with your own hands.

Time Estimates: Hands-On Time vs. Drying Time

| Task | Active Time | Drying/Cure Time |

|---|---|---|

| Cutting & Drilling | 1.5 hours | — |

| Assembly | 1 hour | — |

| Sanding | 1 hour | — |

| Finishing | 0.5 hour | 8 hours (drying) |

| Total Build Time | 4 hours | 8 hours (wait time) |

Here’s how your build weekend might look:

- Cutting & Drilling (1.5 h):

This includes measuring, marking, and cutting all panels and stretchers to size, plus drilling pocket holes on each shelf and cross-piece. With a circular or miter saw and a pocket-hole jig, this goes quickly—even for beginners. - Assembly (1 h):

Using clamps and a cordless drill, you’ll fasten the structure together, align it square, and attach the support strip and toe stops. With pocket-hole joinery, this step is both strong and simple. - Sanding (1 h):

Begin with 120 grit to remove saw marks, then progress to 180 and 220 grit for a silky-smooth finish. Sand edges and corners thoroughly—especially if young children will use the rack. - Finishing (0.5 h + 8 h drying):

Apply wood conditioner (if staining), followed by your stain or paint. After the color sets, brush on 2–3 coats of clear polyurethane, sanding lightly between coats. While active work here is brief, plan for at least 8 hours of drying/curing time between coats to ensure a smooth, durable result.

Weekend Ready:

This project is easily achievable over a Saturday and Sunday, especially if you allow stain or topcoat to dry overnight. You can even complete the hands-on portion in a single day and let the finish cure overnight.

Final Thoughts & Next Steps

Congratulations—you’ve just completed a handcrafted, modern three-tier shoe rack that’s not only functional but also a testament to your creativity and skill. By following this comprehensive guide, you’ve gone beyond simply solving a storage problem—you’ve built something that adds warmth, organization, and craftsmanship to your living space. And the best part? You did it for a fraction of the cost of store-bought alternatives, all while learning foundational woodworking techniques that will serve you for years to come.

What You’ve Accomplished

- Created a durable, stylish shoe rack using solid lumber, quality joinery, and a smooth finish that holds up to daily wear.

- Learned essential woodworking skills, including accurate measuring, pocket-hole joinery, sanding, staining, and applying protective finishes.

- Completed a rewarding project that can be finished in a weekend, even with minimal tools or experience.

Your custom rack now holds 12–15 pairs of shoes neatly, keeps your hallway or foyer organized, and reflects your personal design preferences—whether modern, rustic, or minimalist.

Bonus Benefit: This kind of hands-on project also builds confidence. Next time, you won’t hesitate to reach for the tools again—and your home will be better for it.

Share Your Project (And Boost Your Blog or Channel)

Don’t forget to document your progress with high-quality photos or short videos. Capture:

- The raw lumber and layout

- Assembly stages

- Close-ups of joinery and sanding

- Staining and finishing steps

- A styled “after” photo in its final location

Why? Because visual storytelling drives engagement. Readers and viewers are more likely to stay on the page longer, revisit your site, and share your content. These are exactly the kinds of user behavior signals that platforms like Google AdSense prioritize when evaluating content quality.

You can also:

- Create a before-and-after collage for Pinterest

- Record a 30-second “reveal” video for Instagram or YouTube Shorts

- Add annotated step-by-step images to your blog post for clarity and SEO

Ready for More? Here Are Your Next DIY Projects

Now that you’ve got tools in hand and sawdust on your apron, consider scaling your skills with one of these easy-to-moderate upgrades:

Entryway Organizer

Extend the height of your current shoe rack and add a vertical panel with mounted coat hooks, a mirror, or floating cubbies. You’ll have a cohesive, built-in look for jackets, bags, and seasonal accessories.

Matching Bench

Widen the top shelf and reinforce it to hold weight, then add a cushion for seating. Great for putting on or taking off shoes—especially useful in mudrooms or narrow hallways.

Floating Shelf Display

Use leftover lumber to build minimalist floating shelves for plants, candles, or décor. These make perfect accent pieces that visually tie into your new shoe rack while giving you more display space.

Pro Tip: Create a “DIY Entryway Makeover Series” on your blog or channel. Readers love themed content they can binge or follow over time, and it builds domain authority with consistent internal linking.

Keep Improving

Now that you’ve built your first (or latest) project, take time to reflect:

- What went smoothly?

- What would you improve next time?

- Which tools or techniques do you want to explore further?

Each project builds your confidence, expands your skill set, and makes you more capable of tackling increasingly ambitious ideas. With just a few basic tools, a little patience, and the right guidance—you can build almost anything.

Pingback: 15 Creative DIY Coffee Table Ideas to Elevate Your Living Space - pademoluxury.com